The Freshpack project aims to establish an active packaging technology that prevents premature spoilage of fresh produce. The technology provides a longer shelf-life by slowing down natural ripening and inhibiting microbial spoilage of fruits, berries, and vegetables. This research-based project is driving the preparation of our novel technology for commercialization. We have worked closely with operators throughout the food distribution chain to explore the best way to integrate the technology into existing production lines. In addition to Finnish operators, we have had global interest from countries including Italy, Japan, and Nigeria. With regard to food packaging legislation and the interpretation of its scope, we have had interesting discussions with the Finnish Food Authority and other food and contact material legislation experts. More comprehensive investigation will begin next year.

Based on discussions with stakeholders, the first fresh produce target category will most likely be berries, because of their valuable price and relatively short shelf-life. So far, we have managed to increase the shelf-life of blueberries and raspberries by several days in a wide range of temperatures. This enables the technology to be transferred to real-life distribution chain settings. After preliminary tests, we will continue with large-scale storage testing including microbial safety evaluation.

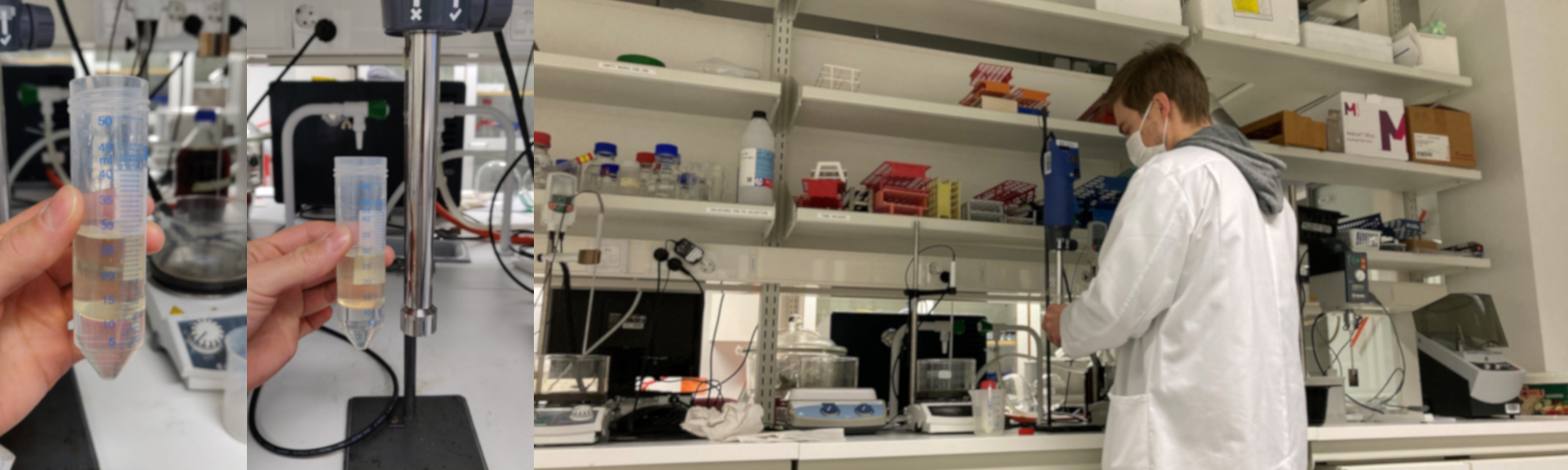

Over the past year, we have worked intensively on overcoming technical issues to ensure that our first minimum viable product (MVP) is easily adoptable at a low cost. The MVP will be a Freshpack pad that simultaneously provides moisture absorption and cushioning properties. Pads are already widely used in the berry packaging industry allowing for effortless implementation into existing production lines. While concentrating on a pad solution, we are also looking for future funding options to gain full benefit from this technology. Future applications will contain more scalable options, for example, coating for cardboard and layers for plastic films.

Despite the current constraints caused by Covid19, we have managed to take the project forward as planned. This is partly due to our expanded team, which grew by two at the beginning of the year. Dr. Mari Lehtonen, who is one of the researchers behind this technology, returned to work on technical development and MSc Kimmo Peltola joined to assist in the laboratory.

Stay tuned for the next updates!

A previously published blog post of the Freshpack project can be found here.