Two years have passed since Abedalghani Halahlah (Abed) who is working as a doctoral researcher commenced in the FinPowder project (here) at the University of Helsinki (Abed, Figures a and b). We are now back to deliver more interesting findings/outcomes to add to the previously revealed results (here) that have already been published as two impactful articles.

First article: Abedalghani Halahlah, Vieno Piironen, Kirsi S. Mikkonen, and Thao M. Ho. “Wood Hemicelluloses as Innovative Wall Materials for Spray-Dried Microencapsulation of Berry Juice: Part 1—Effect of Homogenization Techniques on their Feed Solution Properties.” Food and Bioprocess Technology 16, no. 4 (2023): 909-929.

Second article: Abedalghani Halahlah, Heikki Räikkönen, Vieno Piironen, Fabio Valoppi, Kirsi S. Mikkonen, and Thao M. Ho. “Wood hemicelluloses as sustainable wall materials to protect bioactive compounds during spray drying of bilberries.” Powder Technology 415 (2023): 118148.

In the first article we revealed that, magnetic stirring is the best choice for preparing wood hemicellulose (glucuronoxylans and galactoglucomannans) feed solutions for the spray-dried microencapsulation of bilberry juice. This is because microfluidization caused a loss of total anthocyanin content of the feed solutions. Furthermore, galactoglucomannans feed solutions formed a gel-like structure within a short time after ultrasonication and microfluidization, making these solutions unsuitable for spray-drying. Here also, we reported, for the first time, the formation of gel-like structures from a pressurized hot water extraction galactoglucomannans solution which was further investigated in a separate study (here). While in the second article, we demonstrated that wood-based hemicelluloses are efficient wall materials for the spray-dried microencapsulation of bilberry juice. The encapsulation efficiency values of wood-based hemicelluloses were relatively high and close to that of gum arabic (∼ 73%). Due to the natural presence of lignin-derived phenolic compounds in the structure of wood-based hemicelluloses, their microencapsulate powders had significantly higher phenolic content and antioxidant activities than gum arabic powders.

The findings of these two studies provide another value-added application of wood hemicelluloses obtained from waste and by products of the forest industry. Wood hemicelluloses can replace the currently used wall materials in the production of high-quality bilberry powders via a more cost-effective method (i.e., spray drying) than those currently used (freeze drying and freezing), thus offering an economic opportunity to bring bilberry products to global consumers. Alongside these financial gains, wood hemicelluloses also bring health benefits by adding dietary fibres and antioxidant functionality to the final products.

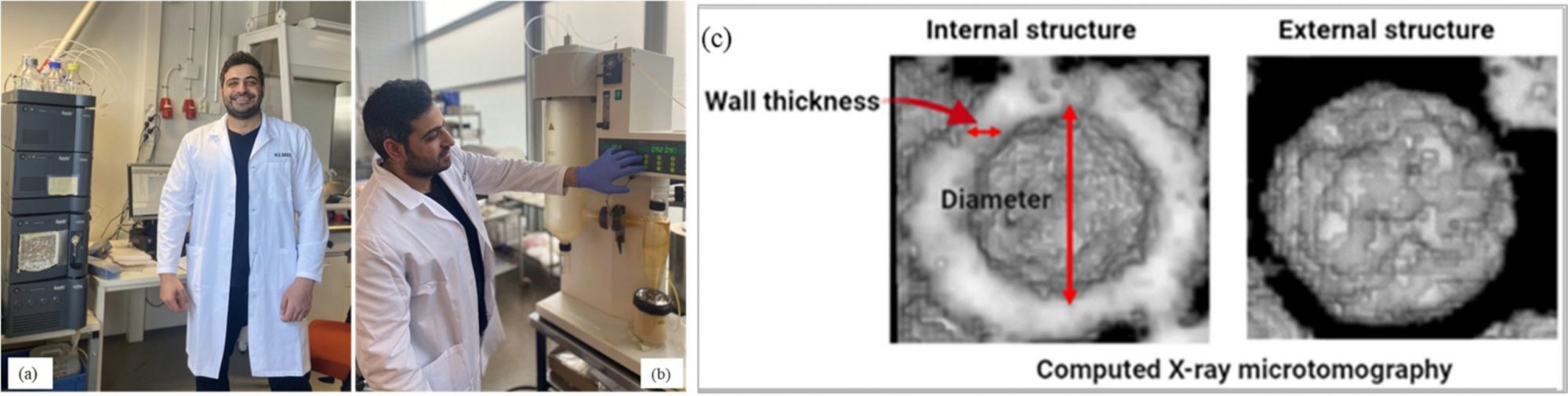

The experimental work was continued by further advancing the functional properties of produced microcapsules, for example by optimizing the ability of wood hemicelluloses to retain and protect bioactive compounds during spraying. In this regard, we carefully planned two models/approaches of experiments to obtain the best bioactive compounds retention and functional properties of the produced microcapsules. The first approach involved the use of carboxymethyl cellulose as a co-wall material combined with wood hemicelluloses to produce the microcapsules at fixed spray drying conditions. During this stage, we also used an advanced analytical technique (computed X-ray microtomography) in collaboration with Department of Chemistry at University of Helsinki to reveal interesting information regarding the internal and external structure and thickness of coating layer of the microcapsules (Figure-c) In the second approach we used wood hemicelluloses alone as wall materials but aimed to find the best processing conditions including inlet and outlet temperatures and the ratio between wood hemicellulose and bioactive compounds (Figure-d). The optimal microcapsules were further analyzed for their phenolic compounds profile including anthocyanins by Ultra-High-Performance Liquid Chromatography (Figure-e).

Luckily, we were able to improve the retention of the bioactive compounds in both approaches with very interesting observations and results that are currently under preparation for publication. The results provide valuable steps towards production of food powders and functional ingredients with high added nutritional values and functional properties with minimal cost.

The FinPowder project has received a third year of funding from the Finnish Natural Resources Research Foundation to conduct further investigations on microcapsule stability and digestibility. In the near future, the optimal microcapsules of wood hemicellulose will be studied for their storage stability over 6 months and in vitro digestion. More to come!

Figure: (a) Abed next to the Liquid Chromatography instrument and (b) conducting spray drying experiments (c) X-ray microtomography images exhibiting the internal and external structure, wall thickness and diameter, (d) The effect of spray drying conditions on the encapsulation efficiency, illustrated as three-dimensional plots and (e) Chromatogram shows 9 peaks of different anthocyanins compounds were found in the microcapsules.