The FinPowder research project funded by Finnish Natural Resources Research Foundation aims to develop a new strategy to offer sustainable and healthy food choices to global consumers while also valorizing Finnish wood-based hemicelluloses and wild berries. Further information about the project can be found here.

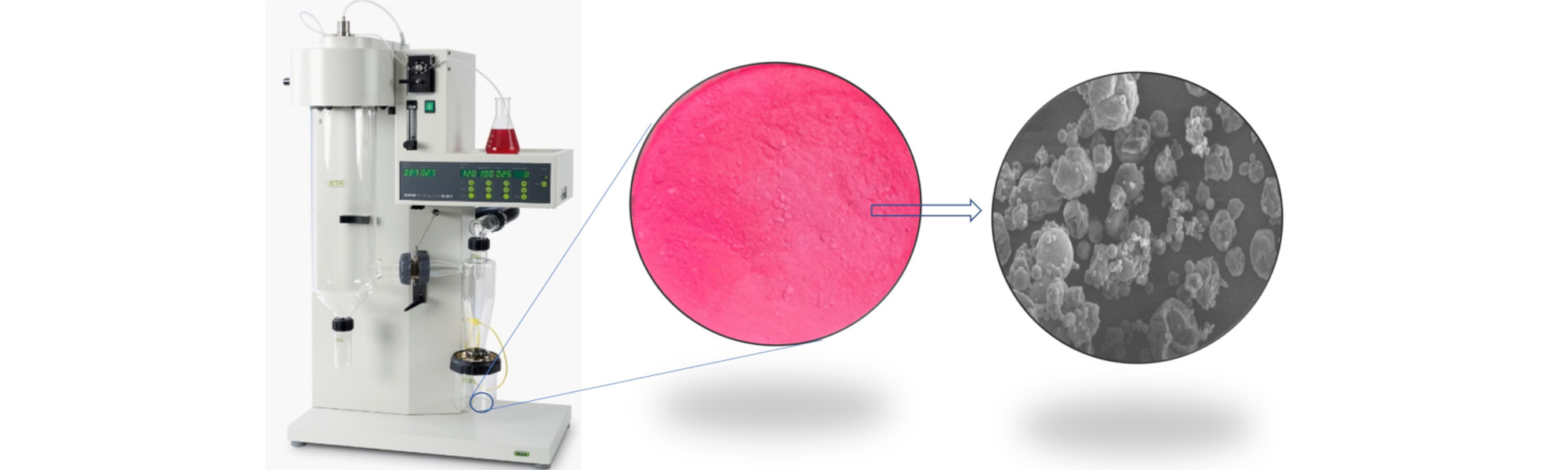

Since FinPowder commenced in April 2021, we have evaluated the suitability of different types of hemicelluloses and celluloses for spray-dried microencapsulation of bilberry juice. We have also optimized the methods for the preparation of feed solutions including bilberry juice, and selected hemicelluloses and celluloses. Thanks to a parallel research project driven by Doc. Fabio Valoppi, a new laboratory spray-drier (B-290, Buchi Labortechnik GmbHDE, Essen, Germany) has been installed in our laboratory (Figure), which has provided a research instrument upgrade that also supports the FinPowder project. Initial results of spray-dried microencapsulation of bilberry juice indicated that hemicellulose had a high retention capacity for bioactive compounds during spray drying with an encapsulation efficiency of 70–80%, similar to that of conventional wall materials (gum arabic and maltodextrin). We used a scanning electron microscope (SEM) to determine the morphology and physical appearance of microcapsule powders coated by sGGM are shown in the figure.

Along with the spray-drier installation, we have worked with a technical engineer from Buchi to successfully design a customized drying chamber which allows the collection of powders at different distances in the drying chamber while they are being dried. We have also installed and carried out testing with a high speed camera system that allows us to investigate the particle powder formation, live. These analyses enable us the first time in this project to characterize microcapsule wall formation happening during the spray-dried microencapsulation process. The FinPowder project has received a second year of funding from the Finnish Natural Resources Research Foundation to conduct further investigation on microcapsule powder characteristics, optimization of the spray-dried microencapsulation process, and investigation on the formation mechanism of microcapsule wall. More to come!

Figure: A Buchi spray-drier, physical appearance and morphology (SEM image, on the right) of bilberry microcapsule powders prepared from hemicelluloses.