Think about expanded polystyrene and try to imagine something that works like polystyrene, but is much more environmentally friendly, very sustainable, and an economic material.

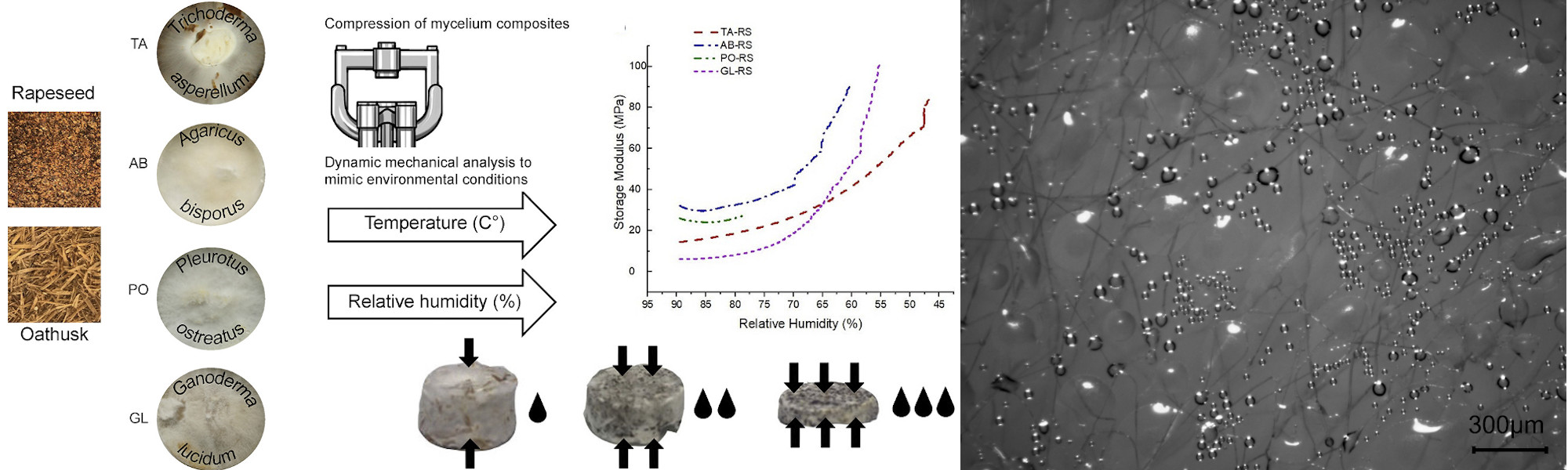

Fungal mycelia are versatile, highly productive, and sustainable sources for biocomposites to replace conventional plastics. However, only a few fungal strains have been characterized in composites and numerous strains remain unexplored. Many plant residue materials, such as side streams from food production could be used as feeding substrates for mycelia. A research article by Zeynep Tacer-Caba et al. explored this field and studied novel fungal strains, feeding substrates, and dynamic mechanical properties of mycelium composites for the first time at a broad moisture gradient. The research was conducted within the Academy of Finland –funded project Reassembly of fungal polysaccharides for biocompatible interfaces (REPLY).

The champion of novel mycelium composites, Agaricus bisporus, gave high stiffness and moisture-resistance. The dense structure and rich chemical composition of rapeseed cake made it a potent feeding substrate for mycelia. In this work, the compressive strength of mycelium composites ranged between 17 and 300 kPa. Therefore, mycelium composites may be considered as competitors of expanded polystyrene, as the latter have similar compressive strength (69–400 kPa).

All tested mycelia composites, either with rapeseed cake or oat husk as feeding substrates, had rather low water uptake at moderate ambient humidity. Therefore, all samples – irrespective of the mycelium and substrate types – seemed to be resilient to moisture. Will future packaging be grown from fungi?